Xiamen Stone Fair 2026 at a Glance

Xiamen Stone Fair is one of the most concentrated global sourcing platforms for natural and engineered stone. For international buyers, the value of the fair lies in supply chain access rather than exhibition scale alone.

| Category | Details |

|---|---|

| Location | Xiamen International Conference & Exhibition Center, China |

| Product Scope | Marble, Granite, Quartz, Quartzite, Engineered Stone, Cut-to-Size Projects |

| Buyer Profile | Importers, Developers, Contractors, Architects, Distributors |

| Strategic Advantage | Integrated quarry-to-export manufacturing ecosystem |

Understanding the Role of Xiamen in Global Stone Trade

Xiamen’s importance comes from structural industrial advantages:

- Port Logistics Strength: Direct export routes improve shipping efficiency.

- Manufacturing Density: Slab production, fabrication, and export services are geographically concentrated.

- Project Fabrication Capability: Factories support large-scale commercial and hospitality developments.

- Export-Oriented Structure: Documentation and compliance processes are built around international trade.

What International Buyers Typically Evaluate in 2026

Professional procurement teams increasingly focus on risk control rather than sample aesthetics.

| Evaluation Priority | Why It Matters |

|---|---|

| Supply Stability | Ensures long-term project continuity |

| Batch Consistency | Prevents costly replacement issues |

| Project Experience | Reduces execution uncertainty |

| Export Compliance | Avoids customs or documentation delays |

| Communication Efficiency | Improves coordination during production |

Key Product Categories to Focus On

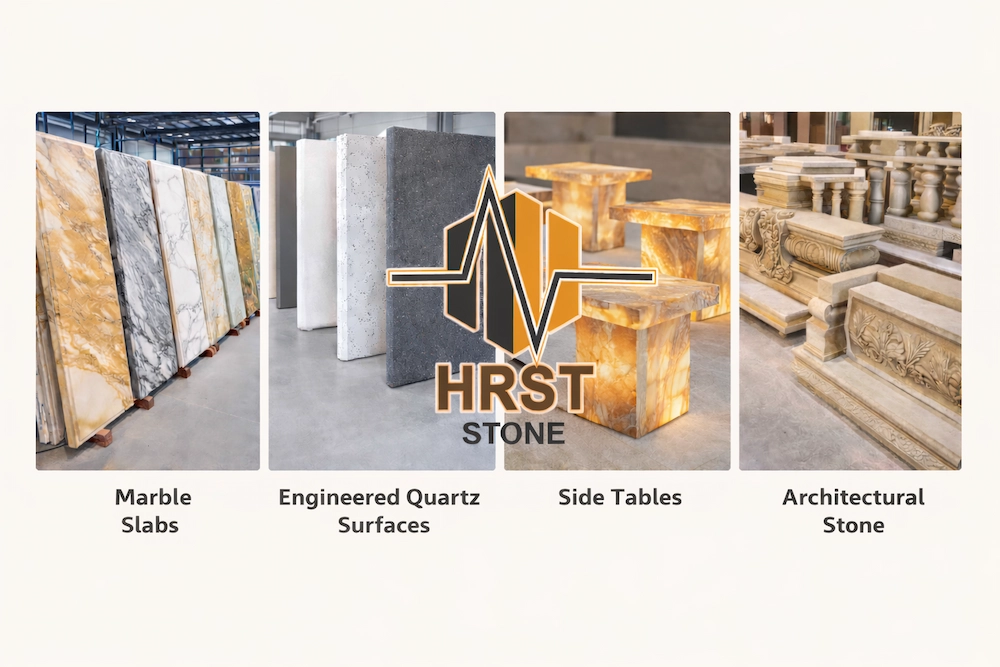

Marble Slabs & Blocks

Best for: Luxury hospitality, villas, commercial interiors.

Engineered Quartz Surfaces

Best for: High-volume residential and distribution projects.

Project-Based Cut-to-Size Solutions

Best for: Hotels, shopping centers, mixed-use developments.

Custom Architectural Stone

Best for: Facade systems and large structural applications.

On-Site Supplier Evaluation: Practical Checklist

| Evaluation Point | What to Verify | Impact on Project |

|---|---|---|

| Factory Background | Years in export, certification, main markets | Indicates operational stability |

| Production Capacity | Monthly output and machinery scale | Determines delivery reliability |

| Slab Grading System | Color classification and labeling | Prevents batch variation disputes |

| Quality Control Procedures | Inspection standards and tolerance range | Reduces dimensional and finish risk |

| Export Documentation | Invoice, packing list, origin certificate | Ensures smooth customs clearance |

Quality Risks Buyers Often Overlook

| Risk | Cause | Preventive Action |

|---|---|---|

| Color Variation | Multiple quarry sourcing | Request batch photos before shipment |

| Batch Inconsistency | Uncontrolled block blending | Confirm block allocation records |

| Surface Finish Deviation | Different polishing standards | Specify gloss tolerance in contract |

| Processing Accuracy | Machine calibration variation | Request dimensional tolerance report |

2026 Material & Design Movements

- Continued demand for neutral and grey marble tones

- Growth of jumbo slab applications

- Expansion of engineered fabrication for projects

- Higher documentation standards for sustainability

From Exhibition to Project Execution

Successful sourcing transitions from exhibition meeting to structured execution:

- Sample confirmation

- Trial or mock-up order

- Contract specification alignment

- Shipping coordination

- Post-delivery inspection

Selecting a Reliable Xiamen-Based Manufacturer

When evaluating a Xiamen-based manufacturer such as HRST STONE, international buyers typically consider:

- Stable quarry resource access

- Integrated slab and fabrication facilities

- Direct port shipment capability

- Engineering-level project support

- International reference projects

HRST STONE emphasizes structured quality control systems and export-ready production standards to support global project execution.

Frequently Asked Questions About Xiamen Stone Fair 2026

Is factory visit recommended after the fair?

Yes. Factory visits provide transparency regarding machinery, inspection systems, and slab storage organization.

How long does bulk production usually take?

Production time depends on volume and material type. Structured scheduling should be agreed in advance.

How can slab consistency be ensured?

Buyers should confirm block allocation, grading standards, and batch photo approval before shipment.

What export documents are required?

Common documents include commercial invoice, packing list, origin certificate, and inspection report.

Final Note / Practical Takeaway

Xiamen Stone Fair 2026 should be approached as a structured sourcing strategy rather than a browsing event. Buyers who combine on-site evaluation, documented quality verification, and controlled trial orders are significantly more likely to achieve stable project delivery. Partnering with experienced manufacturers such as HRST STONE enables procurement teams to reduce supply risk, maintain batch consistency, and build long-term cooperation beyond the exhibition itself.