Why Facade Material Decisions Fail in Commercial Projects

In commercial and hospitality projects, facade materials are often chosen from small samples and renderings. The problem is that samples show surface appearance, but they do not show system behavior. At scale, what matters is wind suction, thermal cycling, substrate alignment, fixing tolerance, handling damage, and long-term cleaning methods.

Most facade disputes happen when teams treat materials as interchangeable finishes. Natural stone and sintered stone can both deliver premium results, but they fail for different reasons. If the fixing method, joint strategy, and tolerance plan are not evaluated together, the project inherits “hidden risk” that only appears after dozens of panels are installed.

Factory Manager: When a facade problem appears on site, it is usually not a single defect. It is a system mismatch—thickness, fixing design, and site tolerance were never tested together under realistic conditions.

A Real Failure Scenario Seen on Site

In one Middle East hospitality project, sintered stone panels were selected to achieve a seamless, minimalist facade. The panels met laboratory performance data, but the system-level behavior was underestimated.

During installation, minor substrate deflection combined with tight joint design caused repeated edge chipping around fixing points. Although each panel passed factory inspection, on-site tolerance stacking led to visible damage across multiple elevations. Replacement panels had to be reordered, delaying installation and increasing logistics cost.

This failure was not caused by poor material quality, but by a mismatch between panel thickness, fixing design, and real site conditions.

Material Reality: Natural Stone vs. Sintered Stone

Natural Stone: Authentic, Strong, and Variable

Natural stone (marble, granite, quartzite) is a geological material. Its main advantage is authenticity: depth, pattern, and light interaction that engineered panels cannot fully replicate. It also offers excellent compressive strength, which supports long-life facade applications when designed correctly.

The trade-off is variability. Even within the same quarry, density and micro-structure can vary by block and sometimes within a single block. That is why natural stone facades depend heavily on slab selection, thickness control, and fabrication discipline.

As a baseline reference in many commercial projects, natural stones used for exterior applications often show water absorption roughly in the 0.2% to 0.8% range (depending on type). Mohs hardness commonly ranges from 3 to 7. These values affect edge durability, abrasion behavior, and long-term weather resistance.

Sintered Stone: Consistent Engineering, Tighter Tolerance

Sintered stone is manufactured under controlled pressure and temperature, which makes thickness and density highly consistent. Water absorption is often below 0.1%, supporting stain resistance and stable surface performance. This consistency is attractive for architects who want predictable alignment and a clean minimalist facade language.

The trade-off is sensitivity. Thin panels are less forgiving of point loads, edge impact, and tolerance stacking. If the project assumes sintered stone will behave like a thick natural slab, problems usually appear during installation: chipped edges, corner stress cracks, or fixing points concentrating stress where the panel is weakest.

Decision Factors That Actually Change Outcomes

1) Height, Wind Load, and Structural Deflection

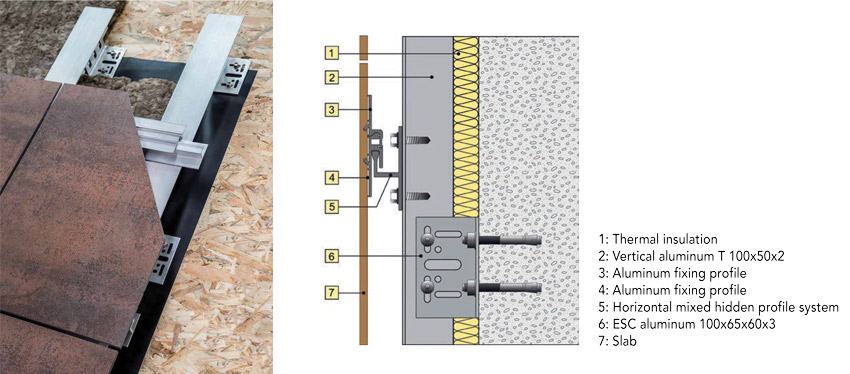

In mid-rise and high-rise buildings, wind suction and structural deflection drive risk. Natural stone systems typically use mechanical anchors designed around slab thickness and predictable load paths. Sintered stone reduces dead load, but it raises sensitivity to fixing design accuracy and alignment. Lighter does not automatically mean safer if the system is less tolerant of deflection.

2) Joint Design and Thermal Movement

Every facade moves. Thermal expansion and contraction are unavoidable. When designs target very tight joints, the tolerance margin shrinks and installation becomes less forgiving. Natural stone can sometimes absorb minor imperfection through thickness and edge behavior, but it still needs a realistic joint and tolerance plan. Sintered stone panels can look seamless, but they demand more discipline in substructure alignment and fixing precision.

3) Maintenance and Replacement Strategy

For commercial buildings, total value is long-term value. Natural stone can develop patina and can be more repairable in some damage scenarios. Sintered stone can remain visually stable, but if a panel is damaged, replacement is often the only practical option. Developers should decide early who owns maintenance responsibility, what cleaning products will be used, and what replacement logistics look like after handover.

Quality Inspector: The biggest risk is tolerance stacking. Each deviation may be “acceptable” alone, but together they push the facade system beyond a safe margin—especially with thin panels.

Dynamic Risk Table: What Goes Wrong in Real Projects

| Risk Factor | 天然石 | Sintered Stone |

|---|---|---|

| Batch consistency | Can vary; requires slab selection and mockup control | Highly consistent across batches |

| Handling damage | Minor chips may be repairable depending on location | Edge chips often force panel replacement |

| Fixing tolerance | Moderate; thicker slabs can be more forgiving | Low; thin panels require higher precision |

| Long-term appearance | May patina; needs realistic expectation and sealing plan | Stable surface; damage may look abrupt |

Cost Is Not Just Material Price

Procurement decisions often compare price per square meter and conclude too early. Facade cost includes fixing systems, specialized installation labor, waste rate, inspection workload, packaging and shipping risk, and replacement probability.

Natural stone costs often accumulate through thickness, selection control, and inspection. Sintered stone costs often hide in proprietary fixing systems, stricter crew requirements, and replacement logistics. The correct question is: which option lowers failure cost for this building exposure and installation capability?

Logistics and Compliance: The Part Designers Don’t See

For overseas projects sourcing from China, logistics is part of risk control. Edge protection, crate design, and packing sequence directly impact breakage rate. If wooden crates are used, ISPM-15 compliance is critical to reduce customs delays and quarantine holds.

Shipping delays can push installation into unfavorable weather windows, increasing site damage and rework. A realistic replacement plan should exist before production begins, not after the first breakage on site.

If you are coordinating specifications, packaging, and inspection checkpoints for a facade project, contact our team. For related decision guides, visit our latest blog posts.

Factory Manager: The safest projects define tolerances, packaging standards, and inspection checkpoints before production starts. If inspection is treated as a final step, problems are already late.

Final Note / Practical Takeaway

FAQ: Natural Stone vs. Sintered Stone for Commercial Facades

1. Is sintered stone better than natural stone for exterior facades?

Not universally. Sintered stone offers consistency and low absorption, but thin panels require precise fixing. Natural stone can be more forgiving in thickness but needs stronger selection and quality control.

2. What technical parameters should buyers request before ordering?

Start with water absorption, Mohs hardness, thickness tolerance, and recommended fixing details. These values help forecast durability and installation risk.

3. Which option is easier to repair if panels are damaged on site?

Natural stone is often more repairable for minor chips depending on location. Sintered stone damage frequently requires full panel replacement.

4. Does ISPM-15 matter for stone facade shipments from China?

Yes. ISPM-15 compliant wooden packaging reduces customs delays and protects schedule risk, especially when replacement panels are needed.

5. When should facade material decisions be finalized?

Before fixing systems and tolerance limits are locked. Material and fixing must be evaluated together as one system.

6. How can a China stone supplier reduce facade risk for overseas projects?

By managing slab selection, inspection checkpoints, edge protection, and export packaging as a single coordinated system.