Ensuring the perfect delivery of luxury marble and quartzite requires a combination of export-standard packaging and scientific container loading. At HRST STONE, we use reinforced fumigated wooden crates, moisture-proof internal wrapping, and precision bracing to prevent any damage during maritime transit. Our “Zero-Damage” commitment ensures your natural stone arrives project-ready, anywhere in the world.

For international buyers, the quality of a stone supplier is measured not just by the beauty of their slabs, but by the condition in which those slabs arrive at the job site. High-end marble and exotic quartzite are significant investments, and any crack or chip during transit can lead to costly project delays. At حجر HRST, we treat the shipping process as an extension of our craftsmanship. You can read more about our industry insights in our latest blog posts.

The Foundation: Export-Grade Reinforcement Structures

Technical Comparison: HRST STONE vs. Standard Export Packaging

| Feature | Standard Industry Method | HRST STONE Standard |

|---|---|---|

| Wooden Crate Thickness | 15mm – 18mm | 20mm – 25mm Solid Wood |

| Internal Protection | Single layer plastic wrap | Triple Layer: Foam + Film + Corner Guards |

| Fumigation Standard | Basic heat treatment | ISPM-15 Full Certification |

| Container Bracing | Simple timber wedges | Custom A-frames + Steel Strapping |

Using ISPM-15 Certified Fumigated Wood

We never use recycled or thin timber. Our crates are built from solid, 20-25mm thick wood that has undergone heat treatment to meet ISPM-15 international standards. This thickness provides the structural integrity needed to support thousands of kilograms without buckling under the dynamic forces of a moving cargo ship. Each crate is further secured with high-tensile steel straps to maintain rigidity.

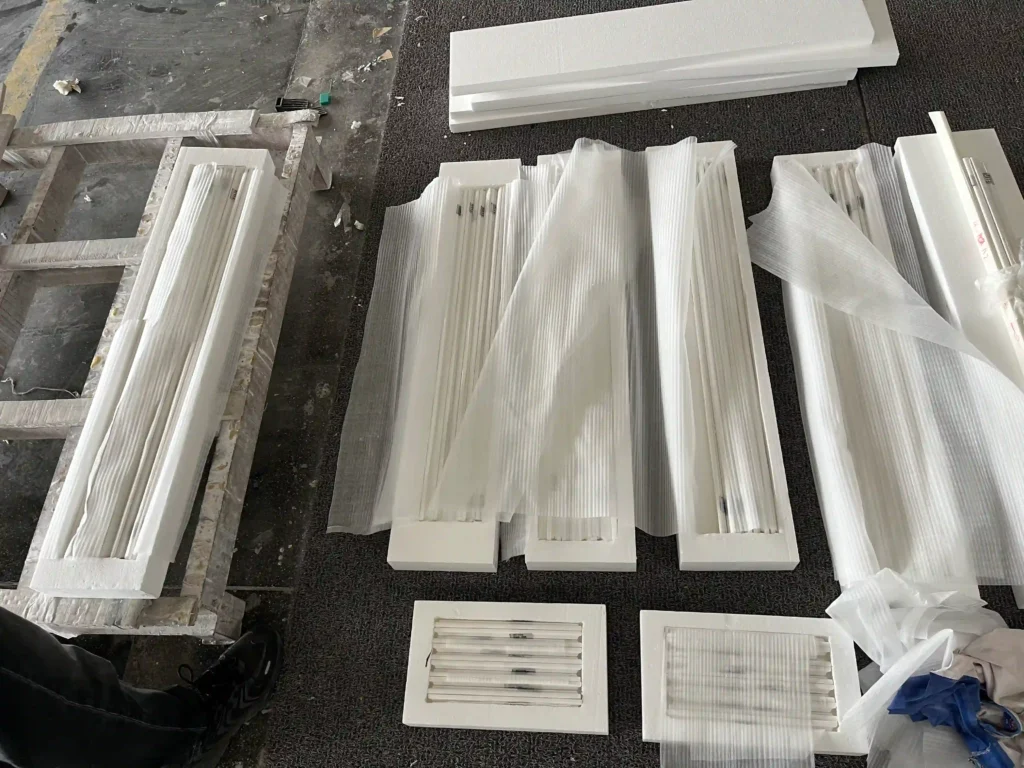

Three-Layer Internal Protection

Each piece of stone, whether it is a custom kitchen countertop or a large-format tile, receives three layers of protection. First, an anti-scratch plastic film protects the polished surface. Second, high-density foam corner guards absorb shocks during forklift handling. Third, industrial shrink wrap creates a moisture barrier, which is essential for preventing oxidation on premium materials like Calacatta Viola marble.

The Science of Container Loading and Bracing

Strategic Weight Distribution

A common mistake in stone logistics is uneven weight distribution. If one side of the container is significantly heavier, it increases the risk of the container tipping during crane operation at the port. Our logistics team calculates the center of gravity for every shipment, ensuring that all crates are positioned for maximum stability during the long ocean crossing.

Timber Blocking and Steel Strapping

Inside the container, crates are not simply placed; they are “locked” into position. We use heavy-duty timber beams to create a secondary skeleton, blocking any potential movement. Combined with professional nylon strapping and air bags to fill gaps, we ensure that your Patagonia Quartzite slabs remain stationary even during rough weather and vessel tilts.

[IMAGE PLACEHOLDER: Professional container bracing and air bags – Alt: Secure stone container loading process at HRST STONE factory]

Expert Insights: Why Professional Logistics Matters

Factory Manager: “The first 5 miles from the factory to the port are critical. We use air-suspension trucks for this leg to minimize vibration before the crates reach the vessel.”

Quality Inspector: “We provide a comprehensive Loading Report for every order. This includes photos of the crate construction, internal padding, and the final braced container with the seal clearly visible.”

Our commitment to excellence makes us a leading partner for global architects. If you are starting a new luxury development, feel free to contact our team for project advice on the best logistics and stone selection.

Packaging is the invisible quality of a stone supplier. Before placing an order, always ask for photos of previous shipments and loading plans. Ensure that your supplier uses solid fumigated wood and a professional bracing system. At HRST STONE, we don’t just sell stone; we deliver peace of mind through engineering excellence.

Frequently Asked Questions

1. How do you prevent marble from cracking during sea transit?

We use zero-gap packaging. By using custom-cut foam inserts and high-density padding, we ensure the stone is completely immobilized. If the stone cannot move, it cannot crack from vibration.

2. What is the standard thickness of wood used for your crates?

We use 20mm to 25mm solid, heat-treated wood. This is significantly thicker than the 15mm industry average, providing a much higher safety margin for heavy natural stone loads.

3. Can you ship marble and quartzite in the same container?

Yes. We organize the container based on weight and fragility, ensuring that heavier quartzite slabs are positioned at the bottom or on reinforced frames to avoid putting pressure on delicate marble.

4. How do you protect the stone from moisture and “container rain”?

Every crate is lined with waterproof plastic and contains industrial-grade desiccants to absorb moisture caused by temperature fluctuations during the ocean crossing.

5. Do you provide insurance for the shipping process?

Yes, we typically offer CIF terms which include premium cargo insurance, giving our clients total protection against unforeseen maritime incidents or damage.

6. What should I do if the packaging arrives damaged?

Take high-resolution photos of the crates before unloading and note the damage on the Bill of Lading. Our reinforced inner packaging often protects the stone even if the outer wood is scuffed.